Iyasaka (Beijing) Automotive Technology Co., Ltd.

Iyasaka (Beijing) Automotive Technology Co., Ltd. was established in 2004 as a joint venture company invested by Iyasaka Corporation and Iyasaka Seiki Corporation of Japan in Beijing, specializing in providing vehicle assembly offline detection systems for the automotive industry. Iyasaka Corporation was founded in Japan in 1944, specializing in the research, development, and manufacturing of automotive testing equipment. By now, it has accumulated more than 80 years of industry-leading technical experience. In 1984, it introduced and established the Iyasaka Beijing Service Department in China. In the process of continuous efforts to develop and innovate, Iyasaka Beijing Company was established in 2004 to better serve domestic and foreign customers.

As an expert in the automotive offline detection system industry, Iyasaka (Beijing)'s product series mainly include: non-contact 3D four-wheel alignment instrument, integrated roller test bench, ABS braking axle weight test bench, headlamp tester, sideslip test bench, steering angle test bench, ADAS integrated calibration platform, AVM calibration platform, Bluetooth key detection equipment, ETC detection equipment, charging inspection equipment, safety test instrument and production line RFID paperless system and other comprehensive solutions.

Iyasaka (Beijing)'s products and solutions are based on internationally leading testing technology combined with the latest domestic technology research and development. They are reliable and stable in quality, have good compatibility and scalability, meet relevant domestic and international technical standards, and can meet the needs of domestic and foreign high-end customers and the market.

Iyasaka (Beijing) has always been committed to introducing cutting-edge global technologies and promoting industry innovation and development. In 2007, it successfully delivered the first complete vehicle testing line in China by introducing internationally advanced technologies, and at the same time developed the first generation of mass-produced automotive bus diagnostic instrument V2; in 2009, the first domestically produced integrated roller test bench was put into production; in 2013, the first domestically produced 3D non-contact four-wheel alignment was successfully developed and delivered to customers; in 2018, it officially launched its self-developed fully automatic ADAS calibration system, and at the same time, the new energy vehicle safety testing equipment was successfully developed and delivered to customers; in 2020, the domestically produced electric floating disc was successfully developed, and at the same time, the fully automatic headlamp testing instrument was successfully developed, and the fully automatic HUD calibration equipment was delivered to customers; in 2021, the commercial vehicle ADAS testing equipment was delivered to customers, and the production line ETC testing equipment was delivered to customers; in 2022, the production line RFID paperless positioning error prevention system was delivered to customers; in 2024, the Iyasaka (Beijing) vehicle offline detection ecological solution was released.

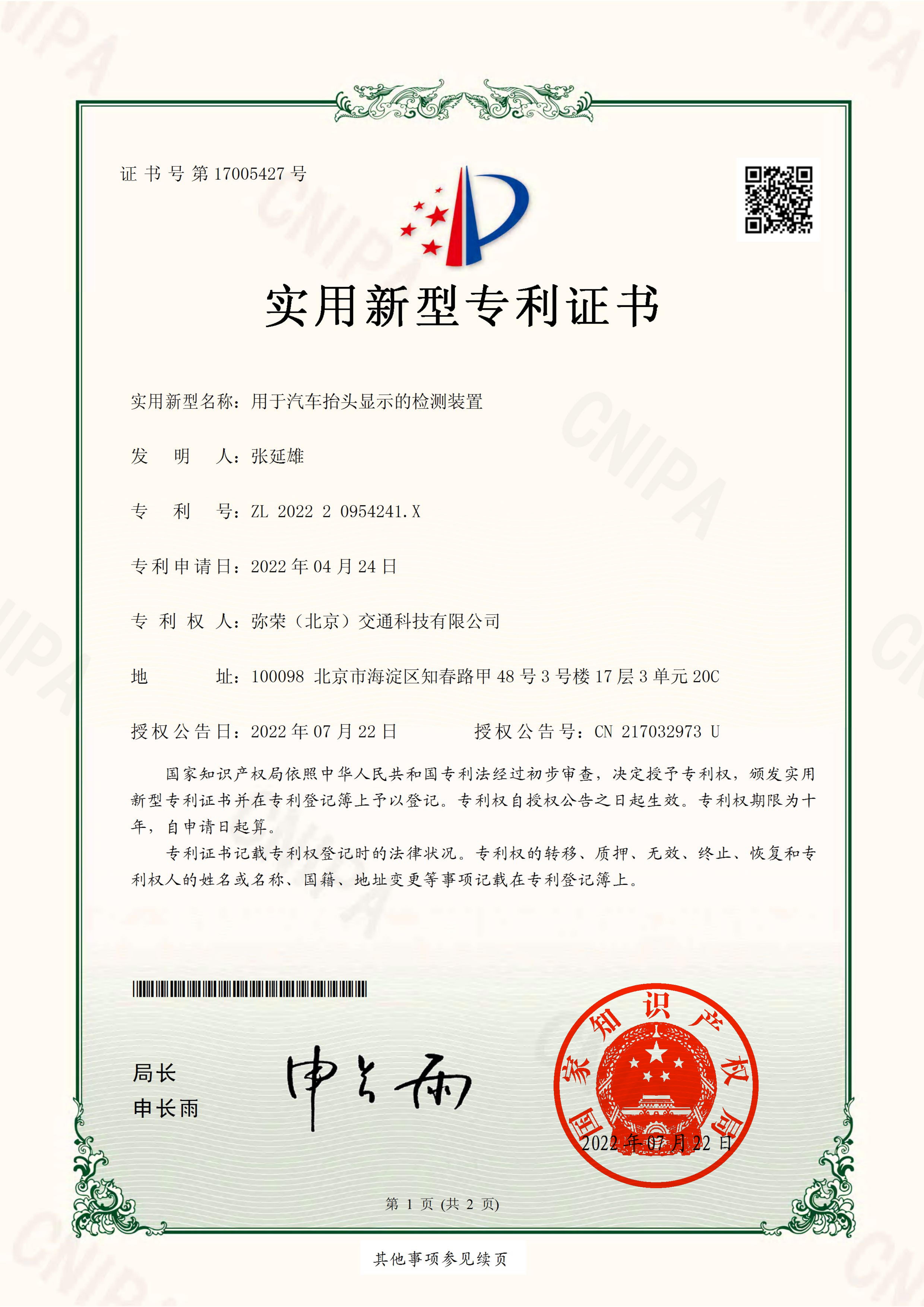

Technological innovation is the driving force for Iyasaka (Beijing)'s continuous progress. R&D personnel account for 80% of the company's total number of employees, and continuous high R&D investment has yielded fruitful results for Iyasaka (Beijing). Currently, it owns 15 national invention patents and 34 national software copyright patents. Continuous technological innovation provides the industry with more advanced solutions to meet customers' new vehicle testing needs.

The company has always been committed to technological research and development, manufacturing, and integration of automotive testing equipment, and at the same time has IS9001 quality system certification and national high-tech enterprise certification. After years of hard work, Iyasaka (Beijing) has become a domestic expert in the automotive offline detection system industry, maintaining good business relationships with many domestic and foreign automotive industry customers, and has gained the trust and recognition of many automotive industry customers.

Core Values

Innovation

- Discover needs, constantly innovate, and continuously improve

- In the increasingly harsh market environment, in order to maintain and enhance competitiveness, innovation is the foundation, and innovation requires huge investment, but it can also stimulate the creativity and entrepreneurial spirit of the team, enabling the enterprise to remain evergreen.

Responsibility

- Practice promises with actions, and fulfill responsibilities with promises

- Responsibility is the commitment of every employee. We not only need to gain customer recognition through action, but also each person should have the ability to take independent responsibility and do things wholeheartedly to provide customers with reasonable solutions.

Collaboration

- Internal and external coordination, mutual respect, and working together

- Our openness combined with our own professional knowledge and efficient internal collaboration capabilities creates value for our customers. Within our company, collaboration is also the source of change and progress.

Management Team

Iyasaka (Beijing)'s vision is to make our travel safer

We provide a variety of vehicle safety testing equipment to customers around the world for vehicle safety assessment and adjustment. Iyasaka (Beijing) has long been a pioneer in innovation and quality, and the continuous introduction and development of new technologies and products ensure the advancement and stability of our products. The future we envision is that we will protect you every time you drive. It is with this beautiful vision that we continuously develop vehicle safety testing technologies, systems, and concepts to make vehicles safer and more reliable, benefiting our lives.

Zeng Debin, General Manager

Iyasaka (Beijing) Automotive Technology Co., Ltd.

More than 80 years of accumulated experience in vehicle offline detection technology is our core competitiveness

We are an automotive testing technology company with a highly innovative team. More than 80 years of technological accumulation and innovation, combined with our product ecosystem and vehicle testing expertise, have enabled us to steadily develop in this rapidly iterating industry.

Baihe, Deputy General Manager

Iyasaka (Beijing) Automotive Technology Co., Ltd.

Development History

-

Release the full ecological solution for offline testing of Beiling lyasaka

Release the full ecological solution for offline testing of Beiling lyasaka

-

Founded by lyasaka Corporation in Japan

Founded by lyasaka Corporation in Japan

-

Beijing IYASAKA Service Department established

Beijing IYASAKA Service Department established

-

IYASAKA (Beijing) Automotive TechnologyCo., Ltd. was established (Sino Japanese joint venture)

IYASAKA (Beijing) Automotive TechnologyCo., Ltd. was established (Sino Japanese joint venture)

-

Successfully delivered the first complete vehicle inspection line - Geely Automobile Inspection Line project, introducing advanced Japanese automotive inspection technology.

Successfully delivered the first complete vehicle inspection line - Geely Automobile Inspection Line project, introducing advanced Japanese automotive inspection technology. At the same time, the first generation of automotive bus diagnostic instrument V2 was developed and mass-produced, and delivered to customers for use in bulk

-

After continuous optimization and technological research and development, the domestically produced comprehensive hub test bench MDT-1000 has been put into operation for the Geely Plateau project

After continuous optimization and technological research and development, the domestically produced comprehensive hub test bench MDT-1000 has been put into operation for the Geely Plateau project

-

Technological upgrades are constantly accompanied by innovation, and the domestically produced 3D non-contact four-wheel alignment equipment WAT-1000 has been successfully developed and delivered to customers for use - Guangqi Honda project

Technological upgrades are constantly accompanied by innovation, and the domestically produced 3D non-contact four-wheel alignment equipment WAT-1000 has been successfully developed and delivered to customers for use - Guangqi Honda project

-

The self-developed fully automatic ADAS calibration system for automobiles has been officially launched.

The self-developed fully automatic ADAS calibration system for automobiles has been officially launched. At the same time, new energy vehicle safety inspection equipment and car Bluetooth key detection equipment have been successfully developed and delivered to customers for use in the GAC New Energy project. VCU flashing equipment has been applied in the GAC Toyota project, and the new generation wheel arch sensor equipment has been delivered to customers in the Hainan Mazda project

-

The domestically produced electric floating disc has been successfully developed and delivered to customers for use in the FAW Hongqi project.

The domestically produced electric floating disc has been successfully developed and delivered to customers for use in the FAW Hongqi project. At the same time, the fully automatic headlight tester has been successfully developed and delivered to the Guangzhou Honda Third Factory project. The fully automatic HUD calibration equipment has been delivered to customers in the Great Wall project in Russia

-

Delivery of commercial vehicle ADAS calibration equipment to customers, and delivery of production line ETC detection equipment to customers in Dongfeng Honda project

Delivery of commercial vehicle ADAS calibration equipment to customers, and delivery of production line ETC detection equipment to customers in Dongfeng Honda project; The new generation of domestically produced 3D non-contact four-wheel alignment equipment WAT-2000 has been successfully developed

-

RFID paperless positioning and error prevention system for automotive production line delivered to customers in GAC Aion project

RFID paperless positioning and error prevention system for automotive production line delivered to customers in GAC Aion project

Certificates of Honor

9

8

7

6

5

4

3

2

1

r1

r7

r6

r5

r4

r3

r2

Partners