RFID automotive production line management solution

Place of origin: China

Manufacturing company: IYASAKA

scope of supply

The RFID-2000 inspection system consists of:

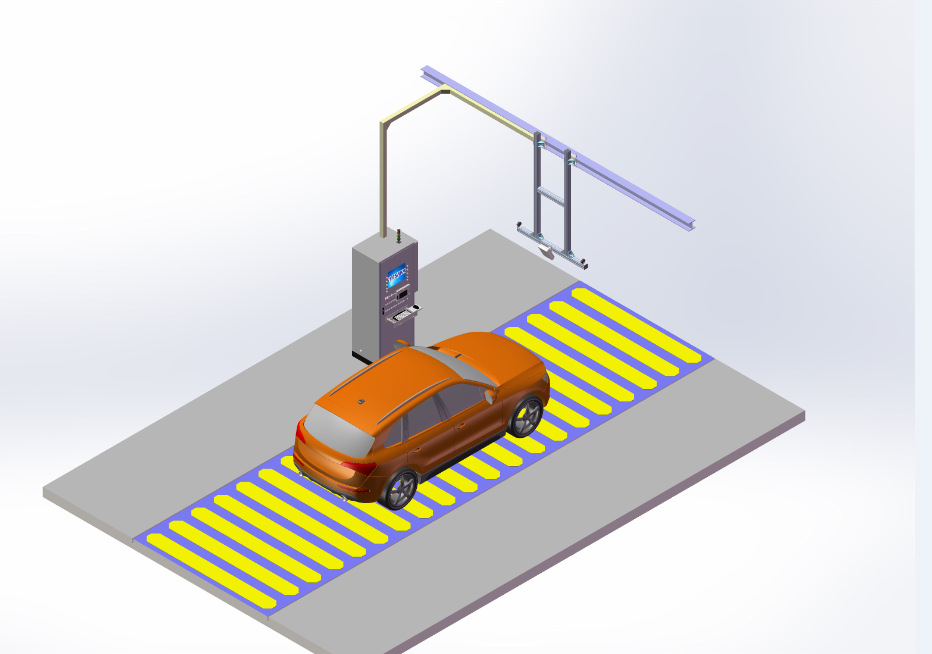

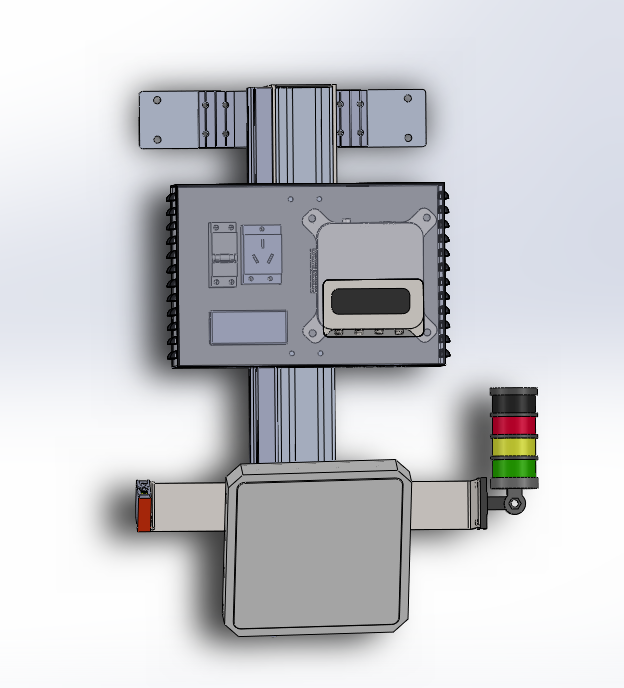

- Hanging structure (or inverted L structure installation)

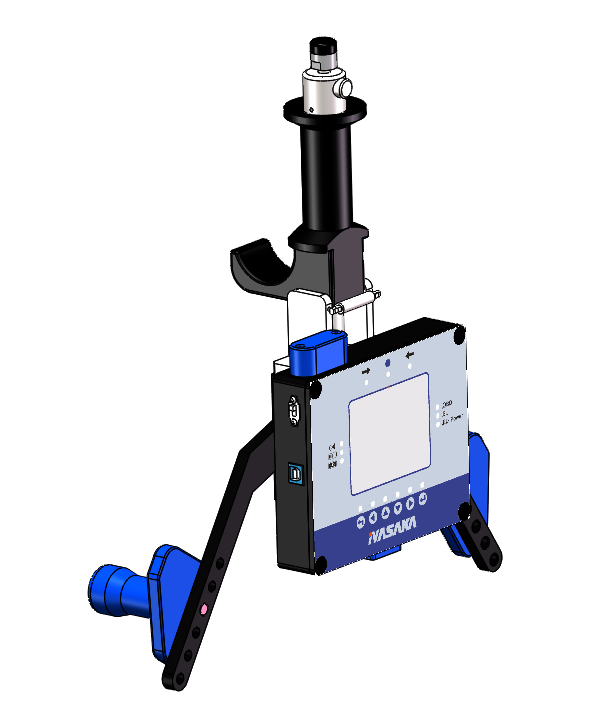

- RFID read write station

- ultrahigh frequency antenna

- Photoelectric switch or ultrasonic sensor (vehicle arrival sensing)

- Electrical control cabinet (including Advantech PC, display, etc.)

- Carry a RFID reader

- Automobile paperless production RFID system management software V1.0

- Server (client can prepare)

- Complete technical data, including Chinese and English data booklets

Purpose of equipment

In view of the needs of automobile assembly plants for vehicle management, IYASAKA provides RFID-2000 offline detection equipment, which is specially designed and manufactured for automobile assembly plants. A unified central database is established in the workshop of the enterprise to facilitate the overall standardized management.

- The use of multi-threading technology makes the time for each station to read the RFID tag is less than 500ms, and the vehicle can complete the scan without stopping when passing at a uniform speed;

- Using the direct reading mode simplifies the architecture of the equipment, and users can easily replace the faulty equipment; it is also convenient to add new sites;

- The modular design enables both photoelectric induction trigger and manual switch trigger to be supported at each station;

- For existing equipment, RFID can be supported without modifying the old equipment.

- The read information is reliable and stable, and the read success rate can reach 100% in standard environment testing

Detection principle

The working principle of Radio Frequency Identification (RFID) is as follows: When an electronic tag enters the magnetic field, it receives radio frequency signals emitted by the reader upon contact. Using energy from induced currents, passive tags transmit product information stored in their chips, while active tags emit signals at specific frequencies. The reader decodes this information and sends it to a central server for data processing

essential parameter

| essential parameter | |

| Wireless protocol | EPC Global Class l Gen 2/IS0-18000-6C |

| service frequency | 920MHz~ 925MHz |

| Read the working distance of the card reader | Maximum 4m, power adjustable |

| label | Waterproof, anti-slip, anti-fall, support for custom log printing |

| From the time the trigger is received to the time the device receives the information | < 500ms |

| Card reader station | |

| way to install | The hoisting distance is 1500mm from the roof |

| Direct current power supply | 12V,3A power adapter, POE power supply |

| Card reader terminal | IYASAKA S LR5623 |

| Comply with the agreement | EPC Class 1 Gen 2 (ISO 18000-6C); DRM support |

| Antenna connections | 4 TNC reverse interfaces |

| CI | 10/100 Base-T Ethernet interface, RS232 GPIO photoelectric isolation 4 input 4 output |

| Status indicator | Power indicator light, status indicator light, antenna indicator light |

| incoming signal | 1x photoelectric sensor switch, which triggers card reading after the vehicle arrives at the destination 1x manual pull cord switch (optional), manual button/ pull cord trigger card reading |

| output signal | 1 red light, card reading failure indicator 1x green light, standby/card reading success indicator 1 yellow light, indicating that the card is being read |

| Photoelectric induction switch | E3JK-DP11 |

| Three-color indicator | LT70-3J ( DC12V) |

| Communicate with the server | Based on factory Ethernet, TCP/IP |

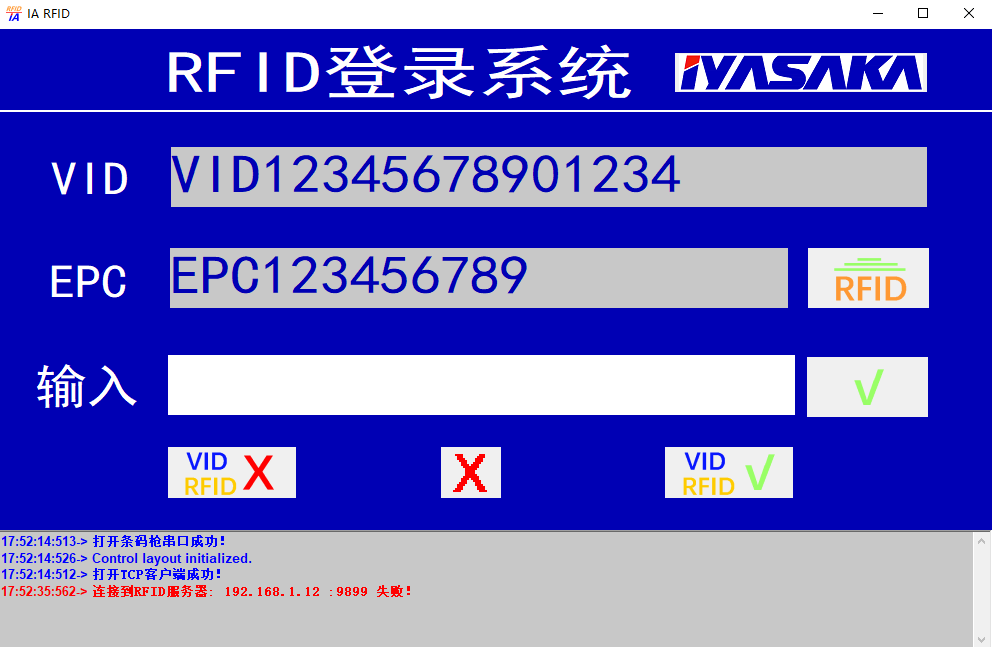

Testing software

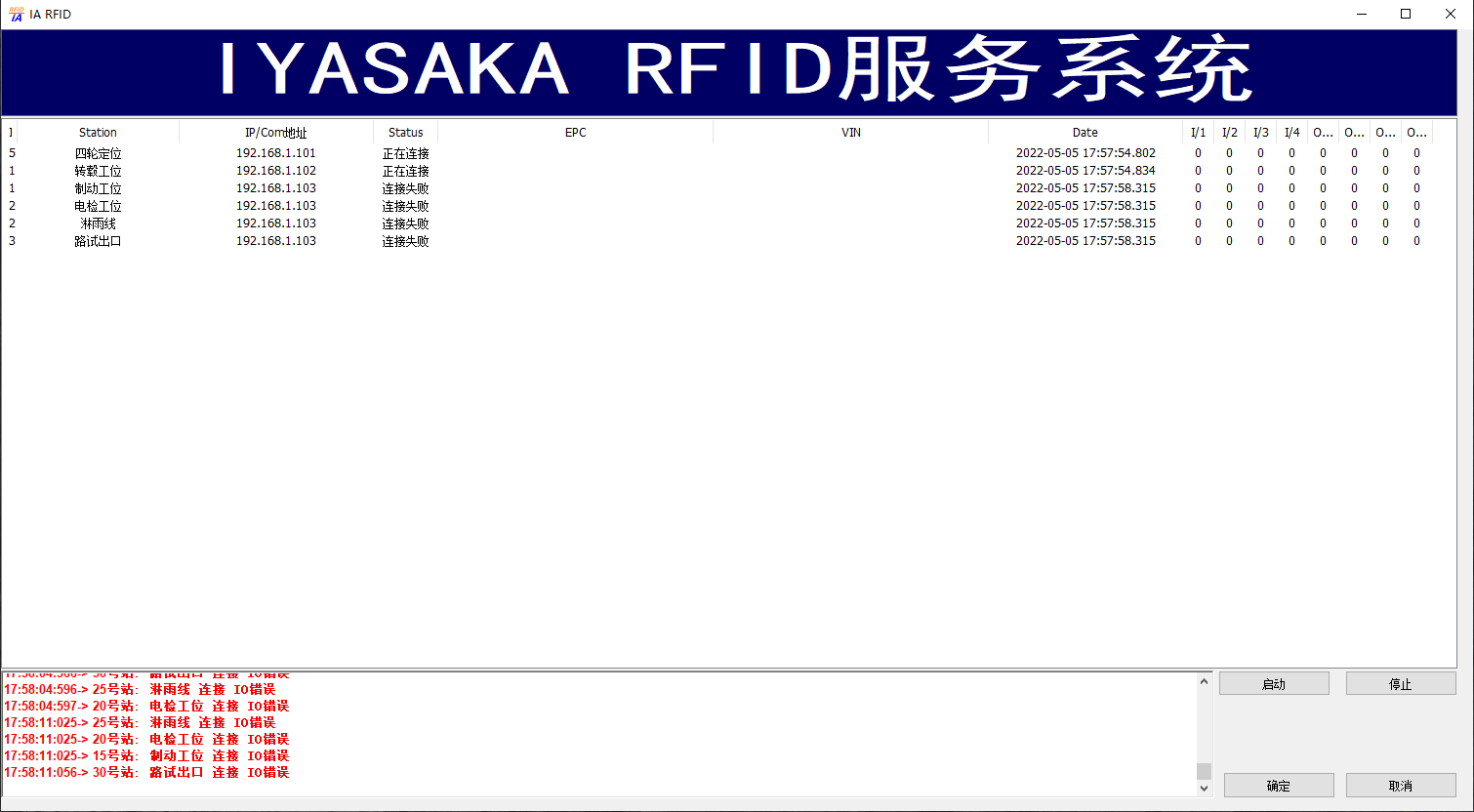

RFID server deployment Mi Rong developed RFID information management software, which can track the data, location, communication and network status of all on-site read/write stations in real time. The collected data is reliable and timely, and the complete operation logs can be viewed at various places. The main functions are as follows:

Card reader status display: can display the status information of each card reader in real time, EPC and binding information and time, view the I/O status of each station and other necessary station information;

Regional information query: can query all the vehicle information of a station in the current position;

Bound information query: can query all the current vehicles that have been bound to E PC;

Real-time data management: When the reader reads the EPC information of the vehicle card, it can timely and effectively send the EPC bound information to the specified device to complete the follow-up work.

Data query and queue query: The regional information of the vehicle can be queried at any time through VIN, and the vehicle information and location can be controlled in real time.

Automobile paperless management system——RFID-2000

Contact Us

Keywords