Electronic Toll Collection System check —— ETC-2000

Electronic Toll Collection Check--- ETC-2000

Place of origin: China

Place of origin: China

Manufacturing company: IYASAKA

scope of supply

The inspection system of ET C-2000 includes:

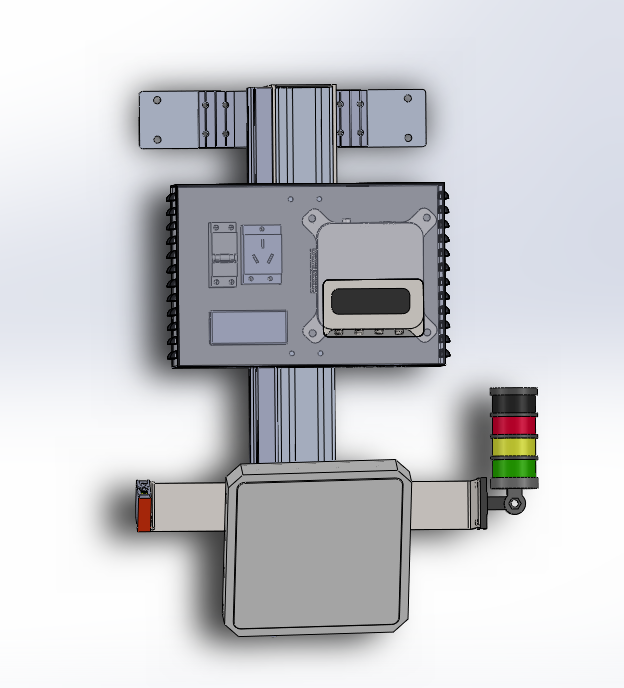

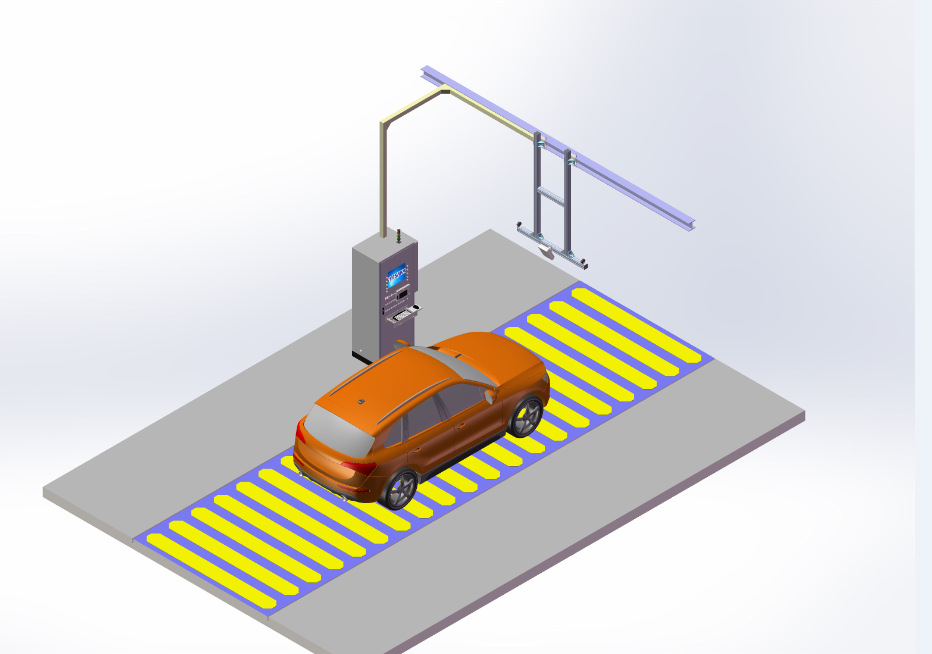

Hanging structure (or inverted L structure installation)

RSU microwave read/write device (default Shenzhen Jinyi)

Photoelectric switch (vehicle position sensing)

Electrical control cabinet (including Advantech PC, display, etc.)

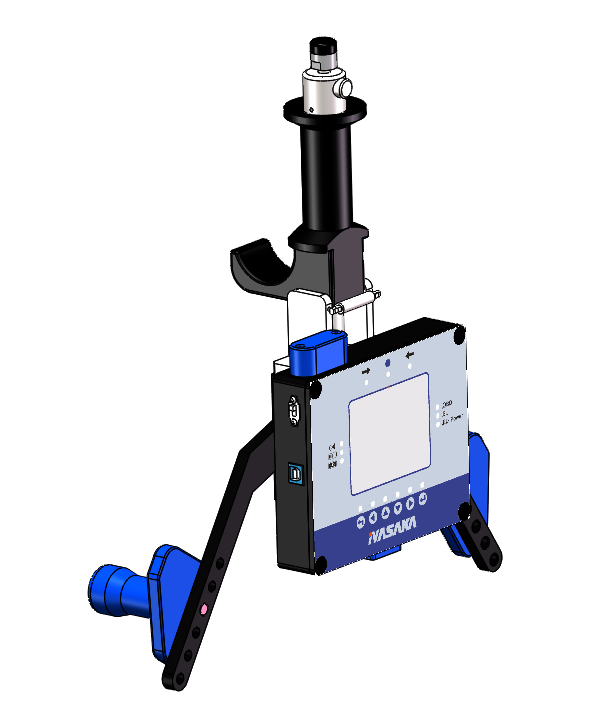

Handheld ETC reader/writer (default Shenzhen Jinyi)

Install the IYASAKA ETC detection APP on the handheld ETC

ETC inspection software IAMachVision For ETC (for OEM online inspection)

Barcode scanner (optional RFID reader/writer)

Complete technical data, including Chinese and English version of data book (including electrical circuit diagram, operation manual, installation manual, etc.).

Purpose of equipment

To meet the demand of automobile assembly plants for ETC detection function of vehicle off-line, IYASAKA provides ETC-2000 off-line detection equipment, which is specially designed and manufactured for automobile assembly plants. It is mainly used for functional test of vehicle ETC on automobile detection line to confirm the normal function of OBU equipment.

Detection principle

The YH Industrial Control Computer connects to RSU devices via Wi-Fi or RS232 serial port. The RSU communicates with the vehicles OBU module through the 5.8G DSRC short-range communication protocol for data transmission and reading. The PAD communicates with the vehicles ETC Bluetooth module via Bluetooth for detection. The host computer also connects to the factory MES system via Ethernet. Pairing information and other encrypted data obtained from the MES system through the VIN code can be transmitted to the vehicles Bluetooth module, enabling dynamic detection of the Bluetooth module in a secure environment

surveillance project

- RSU and OBU communication function check (mandatory)

- Check the communication function of ETC Bluetooth module (check)

- Simulated transaction function (selected by qualified automobile factories)

reference standard

- Refer to the standard GB/T 20851.1-2019, Electronic Toll Collection Special Short-range Communication

Check the beat

Less than 33 seconds (normal ETC).

Electronic Toll Collection Check——ETC-2000

Contact Us

Keywords