Driver Assistance Calibration System-ADAS-2000

Driver Assistance Calibration System-ADAS-2000

Advanced Driving Assistance System

Place of origin: China

Manufacturing company: IYASAKA

Equipment name and model

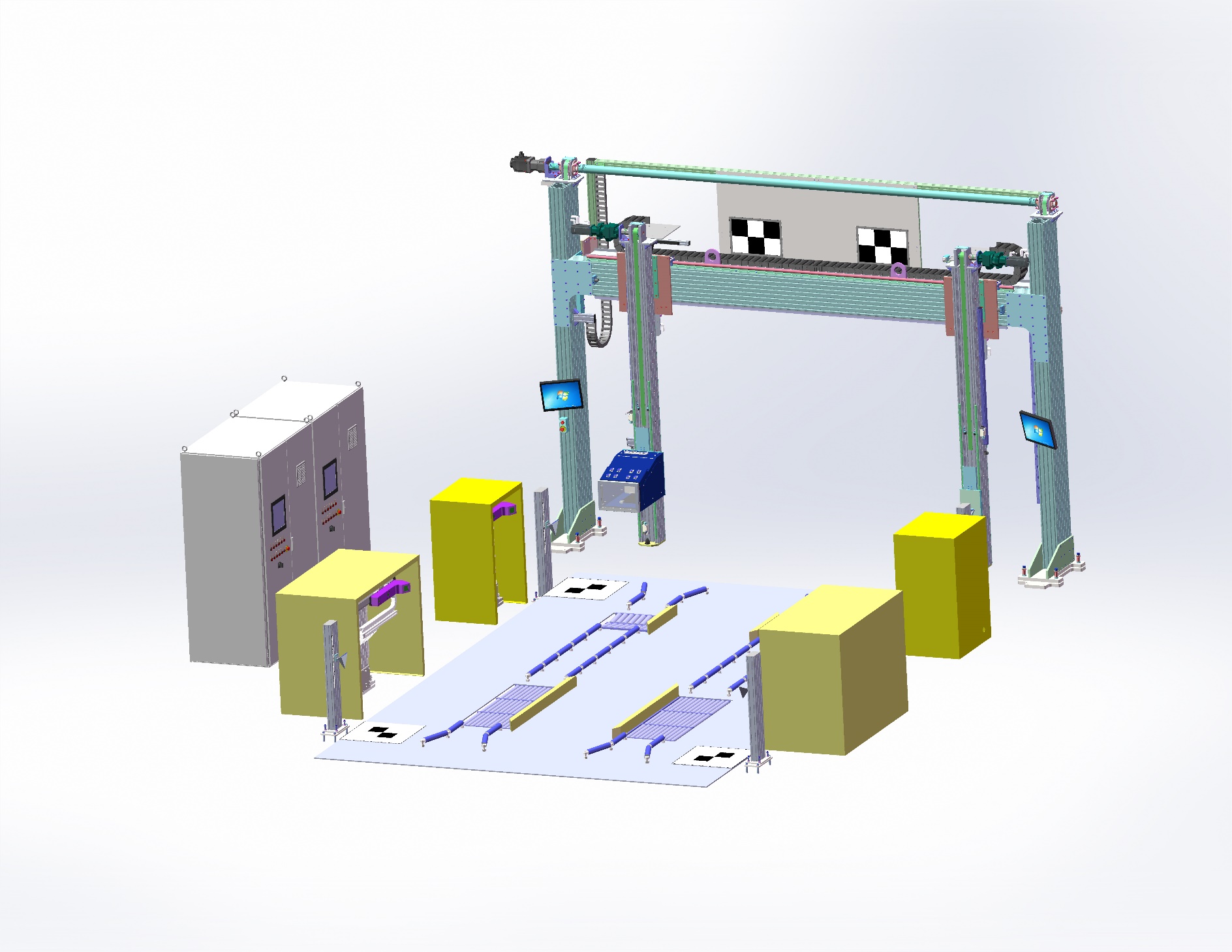

The ADAS-2000 advanced driver assistance system includes:

Aluminum alloy gantry

- Vehicle alignment

- Passive ACC light box (including CCD camera and Fresnel lens)

- Active ACC metal target

- LDW black and white pattern target for front/back camera

- Front/back angle radar BSD triangle target

- Rim and eyebrow height measurement system (optional)

- Laser emission standard target (optional)

- Electrical control cabinet (including PLC, servo driver, industrial computer, etc.)

- Adas calibration software IA-ADAS (for online adjustment in the car factory)

- Driver assists display

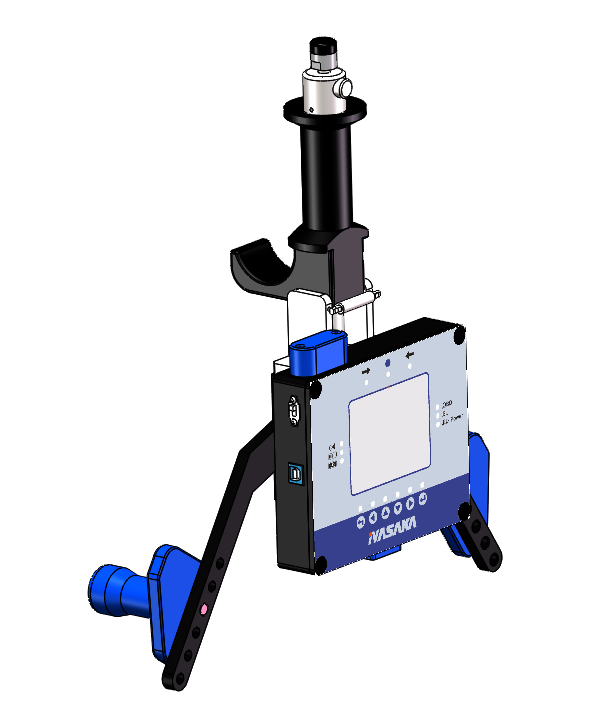

- Calibration stand (for calibration)

- Complete technical data, including Chinese and English version of data book (including electrical circuit diagram, operation manual, installation manual, etc.).

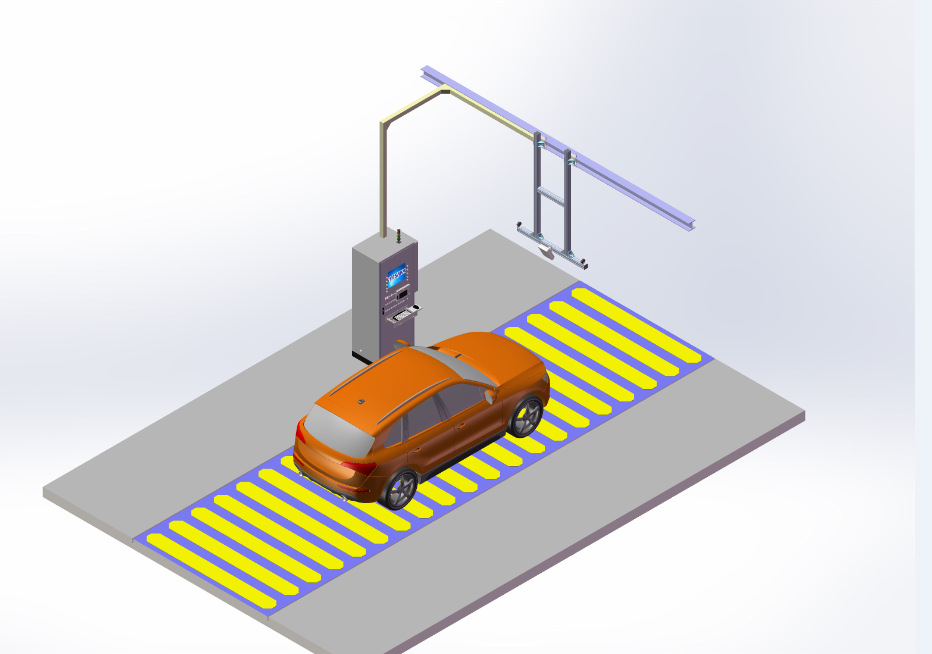

Detection principle

The system employs dual pneumatic control alignment mechanisms at both ends, enabling the alignment lever to drive wheels symmetrically along the equipments geometric centerline. This ensures both front and rear wheels align precisely with the equipments central axis. The alignment device maintains vehicle levelness with ≤±1mm tolerance across any XY plane point. Servo motors drive multiple functional targets to designated positions, while IYASAKA proprietary ADAS calibration software communicates with the vehicles ECU. This enables precise adjustment of sensor installations (including cameras, radar, LiDAR, etc.) in terms of positioning, orientation, coordinate systems, and alignment with other vehicle systems. The system guarantees that sensor data matches real-world physical space, ensuring accuracy and reliability for ADAS features like lane-keeping, adaptive cruise control, and automatic emergency braking.

surveillance project

ACC/FCW front collision warning;

- LDW lane offset calibration;

- BSD blind zone monitoring and calibration;

- Measuring the height of the rim;

- SVM/360 Panorama impact calibration;

- HUD calibration (optional);

- Laser emission calibration (optional)

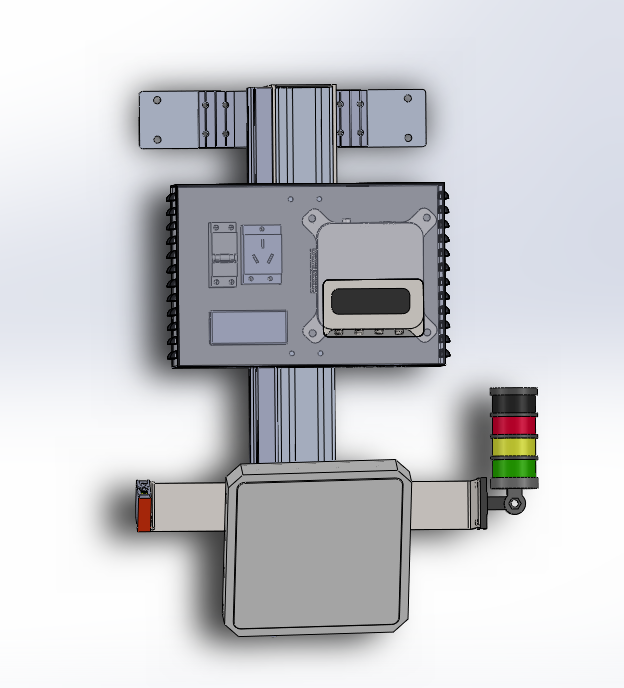

GM diagnostic instrument VCI5

- Supports 4 CANFD/CANBUS bus data transmission;

- Connect the cars BD cable to power the diagnostic instrument;

- Supports Bluetooth wireless and 232 serial port cable transmission;

- Support multiple automotive bus protocols

- Support the secondary development interface function of the host computer.

- Integrated with 4 C ANFD/CANBUS communication modes;

- Supports 1 K bus communication mode;

- Integrated with 1 DOIP bus communication mode;

- Wireless and wired automatic switching;

- The signal light indicates the working status

essential parameter

| Main technical parameters of automotive suspension device | |

| Allow maximum load capacity | 3t |

| Allow the wheelbase of the car | 2200-3200㎜ |

| Allow wheelbase | 1400-1600mm |

| Front panel width | 1000㎜ |

| Width of rear panel | 1200㎜ |

| Thickness of mobile panel cover | 8mm |

| accuracy of alignment | Left and right: ±2mm; front and back: ±5mm |

| Time to respond | <2s (adjustable) |

| Frame splicing mode | Rectangular tube welding, bolted connection |

| The China Way | plate-type |

| levelness | ±1mm |

| Mobile mode | Rail type |

| Guide rail lubrication | PLC controls the oil pump to concentrate on refueling |

| In place testing | Front double pair photoelectric limit block |

| way to install | The installation of the pit (the length of the pit is 5.4m and the width is 2.9m) shall be determined through negotiation |

| Leveling mode | Adjust the shank |

| Calibration method | Equipped with calibration equipment |

Range and precision

| Measurement range and accuracy | ||

| project | scope | accuracy |

| Target target speed | Level Y: 250mm/s Vertical Z: 250mm/s | ±5% |

| Targeting | X: 300~ 1200mm (customizable) Y: -1300~1300mm (customizable) Z: 300~ 1200mm (customizable) | ±1mm ±1mm |

Check the beat

Less than 50 seconds (no adjustment required).

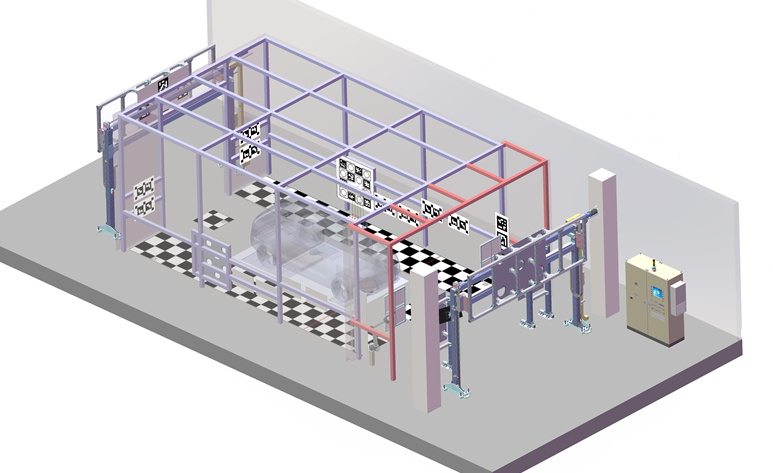

Case drawing

Driver Assistance Calibration System——ADAS-2000

Contact Us

Keywords