Headlight height check —— HLC-2000

Head l ight Check---HL C-2000

Head l ight Check---HL C-2000

Place of origin: China

Manufacturing company: IYASAKA

scope of supply

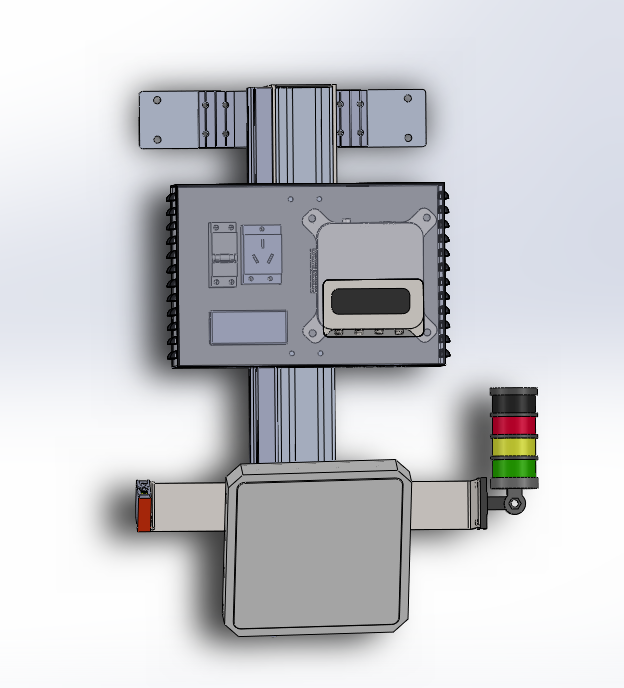

The HL C-2000 headlight height inspection system includes:

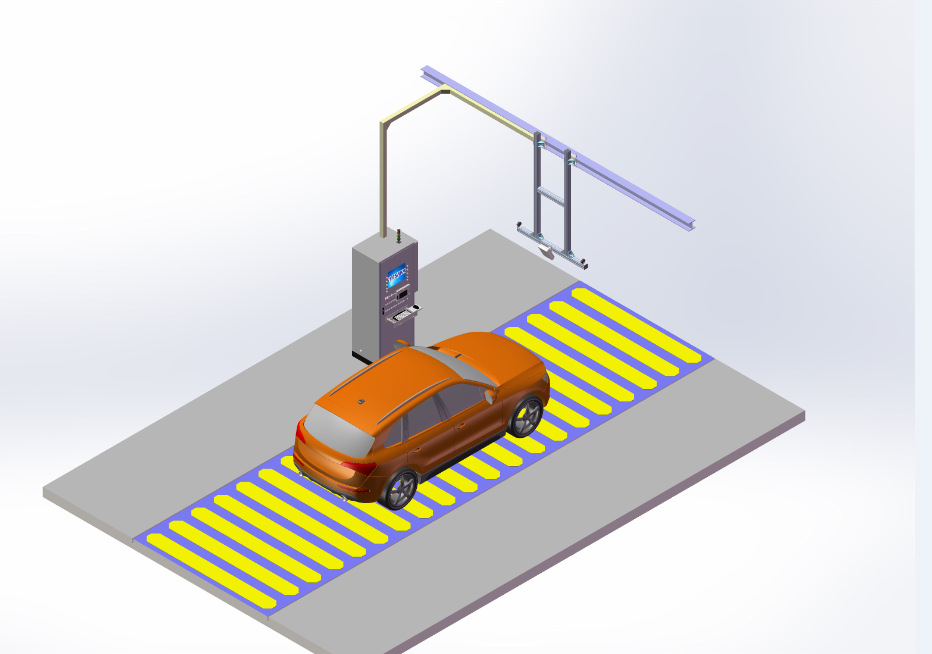

- Hanging structure (or inverted L structure installation)

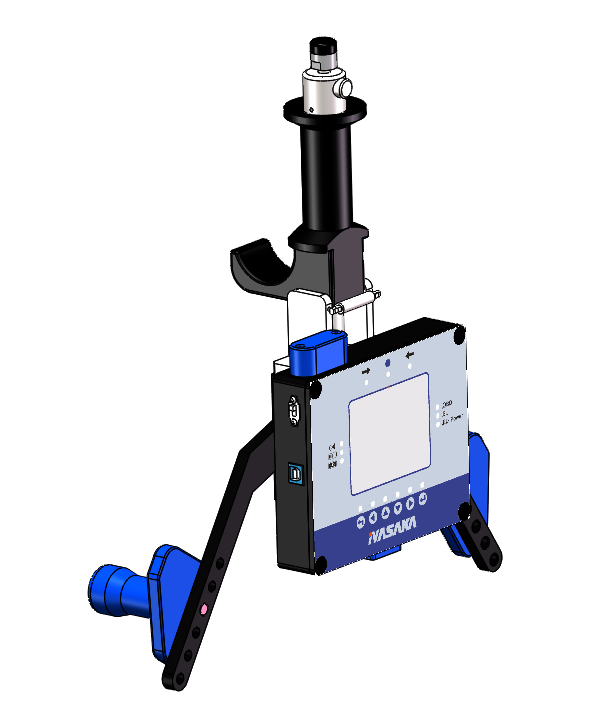

- Camera module (including CCD color camera, two sets of laser and laser automatic adjustment motor)

- Electrical control cabinet (including Advantech PC, display, motor control, etc.)

- Light height inspection software IAMachVision For HLC (for OEM online inspection)

- Barcode scanner or RFID reader (option)

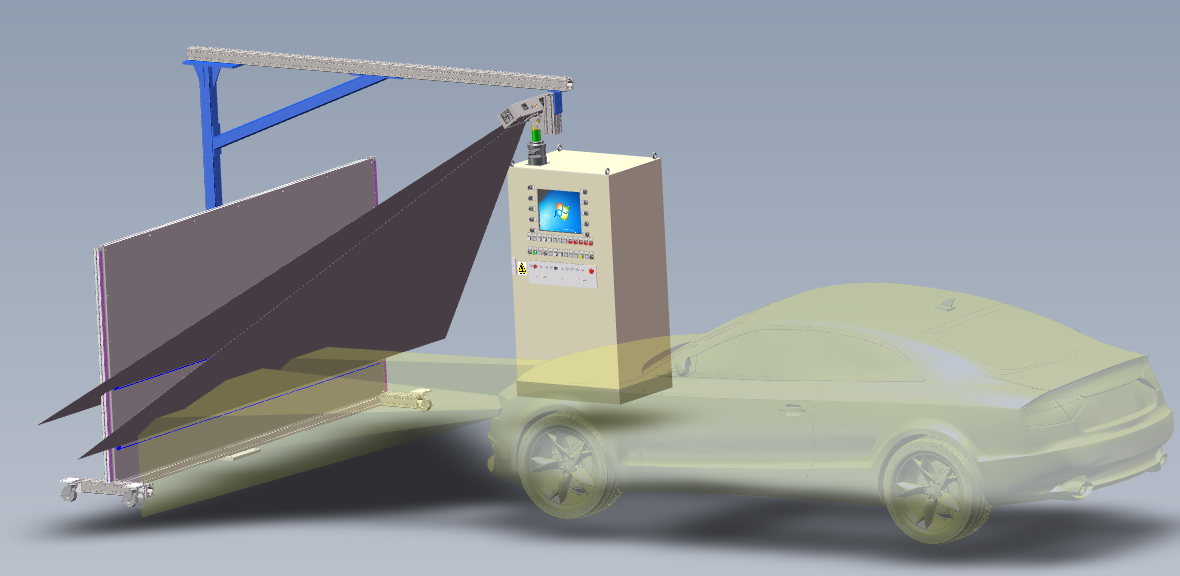

- 10-meter board (with physical scale)

- Black and white pattern board (for calibration)

- Complete technical data, including Chinese and English version of data book (including electrical circuit diagram, operation manual, installation manual, etc.).

Detection principle

The headlight modules of different vehicle models have distinct height thresholds on a 10-meter whiteboard. A stepper motor driven via the 485 bus controls dual linear lasers to project light patterns at corresponding upper/lower limit positions, enabling driver inspection. Digital CCD industrial cameras precisely regulate exposure parameters and capture light pattern images. These images are transmitted to an industrial computer at 20-40Hz frame rate through GigE protocol. IYASAKA proprietary light height measurement software automatically identifies the cutoff line between illuminated and shaded areas projected on the 10-meter board. Based on predefined standards, it determines whether the headlight height falls within specified limits, completing the inspection process.

surveillance project

- Left/right front headlights far and near light range;

Measurable light type

Halogen lamp, HID xenon lamp, LED lamp (LED lamp strip and LED lamp group), laser headlights and four axis lights, etc

- ECE European light type, SAE American light type, JPN Japanese light type

- It can be used for detection of common near light distribution such as L-shaped and Z-shaped

essential parameter

| Test height (camera module axis center to ground) | 2200mm |

| Test distance (distance from the camera module axis center to the 10-meter board) | 2200mm |

| Size of 10-meter board | 3000mm*1500mm |

Range and precision

| Measurement range and accuracy | ||

| project | scope | accuracy |

| High light range | 300~1400m m | ± 1 0 m m |

| Laser angular resolution | 0.02° | |

| Camera module positioning | Y: 0 mm Z: 2200 mm | ± 2 mm ± 2 mm |

Check the beat

Less than 20 seconds (no adjustment required).

Headlight height check——HLC-2000

Contact Us

Category

Keywords