Integrated hub testing equipment —— MDT-2000

— MDT-2000

— MDT-2000

Place of origin: China

Manufacturing company: IYASAKA

Testing concepts

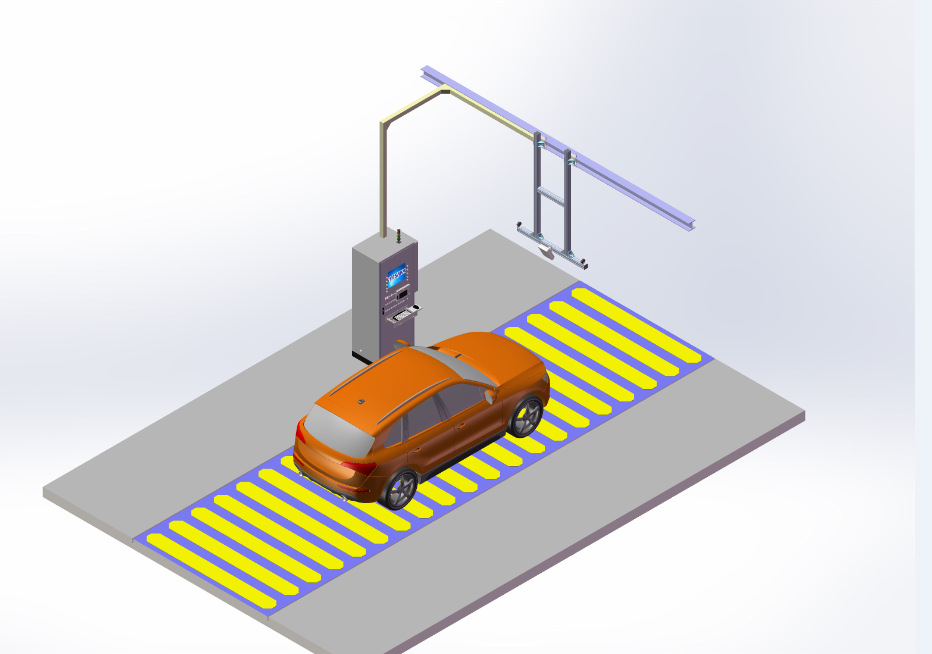

This system measures and evaluates vehicle parameters including speed, acceleration, braking force, driving force, parking force, speed sensors, ABS, ESP, VSA, and tachometers. It simulates various dynamic driving scenarios in road-like environments. The system performs high-precision measurements of speed, driving force, and braking force during testing, while enabling data acquisition and computational analysis to ultimately determine compliance with standards.

The equipment meets the relevant provisions in the latest version of GB7258-2017 "Technical Conditions for Safe Operation of Motor Vehicles".

The drum test bench is equipped with functions such as high-speed drum detection, dual-axis braking force detection, and electric vehicle testing. The equipment meets the technical requirements of GB/T13563-2007 "Speedometer Inspection Bench for Drum-Type Vehicles" and JJG909-2009 "Calibration Regulations for Speedometer Inspection Batches for Drum-Type Vehicles".

test item

Transmission function test (AT/MT)

- Thrust test

- Speedometer

- Speed test on the road

- ABS/ESP test

Product features

More test functionality and higher test quality

- High measurement accuracy, small repeatability error and stable operation

- The modular design is simple to arrange, easy to maintain, high cost performance, low maintenance cost and use cost

- Actual road resistance simulation

- The motor drive system is controlled by a four-quadrant full digital AC driver.

- Based on servo drive control technology, it has better static and dynamic characteristics

- High speed communication, convenient interface and help document operating interface

- Flexible open control platform, using IEC61131 standard programming

- Built-in control software, comprehensive process control and various safety functions, more reliable use

- The rectification mode is IGBT active rectification, the power factor is close to 1, and it is not affected by the power grid fluctuation

- Wide power supply voltage range (380-480V±10%; 48-67Hz)

scope of supply

MDT-2000 integrated hub turning equipment includes:

| Supply scope and service | |

| driving system | 4 x 55kW heavy duty motor 4 x 55kW heavy load transducer |

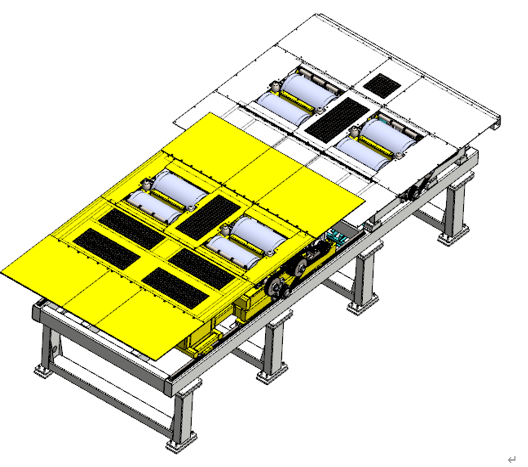

| rollers set | diameter :502mm Roll length: 800mm Mode: double drum/unit 4 units/stands |

| Axis adjustment system | Axle spacing adjustment speed: more than 60mm/s; Axle spacing adjustment accuracy: ±1mm. |

| constrained system | Two limit safety rollers on the rear axle to prevent the car from withdrawing backward from the test bench Two limit safety rollers on the front axle to prevent the car from withdrawing forward from the test bench 4 lateral limit pulleys: to avoid damage to the tire and rim caused by the lateral movement of the car (mechanical) |

| lifting jack | One set for each front and rear axis Lift capacity: 1000kg/ wheel |

| Waste gas collection | Two sets of flaps corresponding to the left and right exhaust pipes Two sets of collection discs (one set at the front axle and one set at the rear axle): used to collect liquid exhaust condensate, coolant, etc. The engine compartment exhaust is sucked at the front axle |

| frame | Pit size: 8200 × 5000 × 2200mm Equipment cover plate and surrounding cover plate |

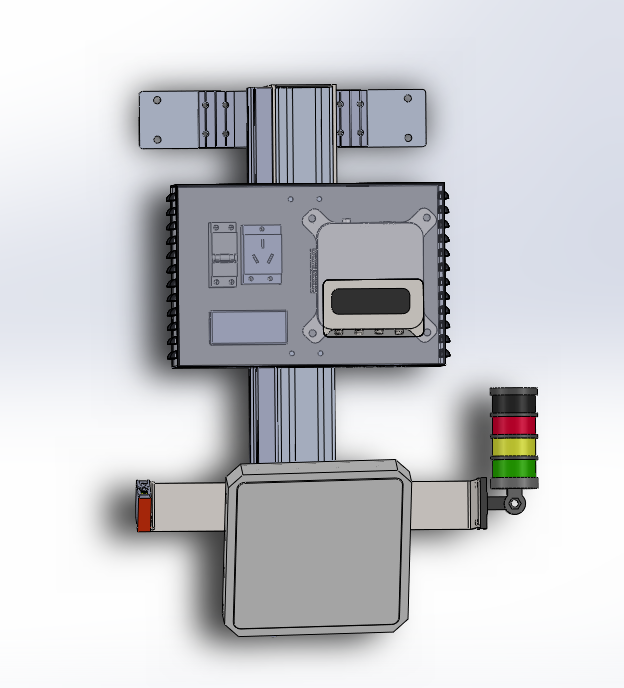

| electrical control cabinet | The Witu PS series has an air-conditioned cooling system Siemens 1500 or other mainstream PLC system PC system, including Advantech 610L industrial computer and UPS and 1 9TFT cabinet door display |

| Vehicle identification | Through the VIN code (barcode and keyboard) Select via remote control |

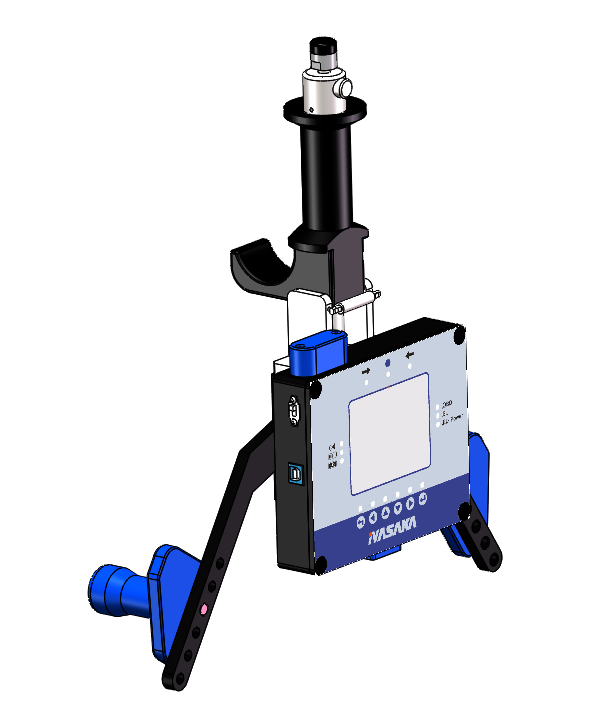

| Driver assistance | 22 TFT is equipped with a protective cover and installed on the left side of 1500~2000 in front of the driver The driver operates the button box and wireless remote control Red and green lights |

| Calibrate the tooling | 1 set of torque calibration device and software: used for the calibration of braking force measurement specified in GB7258-2017. One speed calibration device and software: used for the calibration of speed measurement specified in GB7258-2017. |

| ABS/ESP test | GM bus diagnostic, customer choice |

| wheel load | Customer selects, measure wheel weight |

| Soundproof room | Customer choice, factory noise standards, front and rear roller shutter doors, etc |

| Hand pull/step force gauge | Sampling, customer choice |

essential parameter

| Maximum allowable axle load | 2000 kg |

| tread | 1200~2000㎜ |

| tyre | Φ400㎜~φ9 00㎜ |

| Roller configuration | Two wheels in the front and two wheels in the rear |

| Inner diameter of drum × outer width (center spacing) | 800mm×2, 400㎜ (1, 600㎜) |

| Roll diameter × length × shaft spacing | Φ 502mm × 800mm × 620 (adjustable) ㎜ |

| Basic inertia of drum assembly | 1000 kg (optional) |

| Shaft speed adjustment mode | Servo motor control, automatic |

| Axis adjustment range | 1940 mm ~ 2840 mm (adjustable) |

| Shaft speed adjustment and accuracy | Greater than 60mm/s±1.0mm |

| Test speed range | 0~1 70km/h |

| Speed test error | Less than 0.1km/h |

| Intermediate lifters | Installed between each pair of rollers |

| jacking capacity | More than 200kg |

| Vehicle drive and simulated moment of inertia section | 4 vector motors, 4 motor drive controllers (frequency converters) + 1 feedback unit |

| Main rectifier cabinet | 1 set |

| Master inverter cabinet | 1 set |

| Control cabinet installation mode | The ground is set up to be self-supporting |

| Set the number | 2 units |

| source | AC380V,50Hz |

| Equipment control mode | Control by Siemens programmable controller |

| Benchmark setting | The electrical control cabinet is equipped with a 19-inch color LCD industrial display, which displays Chinese |

| Operation of main circuit breaker | Use an external controller |

| presentation of information | TCP/IP |

| Three coloured lights | The red light flashes when there is a fault; the yellow light flashes when the equipment is tested normally; the green light flashes when the vehicle can enter |

| buzzer | The device will give an alarm when it fails |

| Control cabinet Air conditioning control cabinet air conditioning | Provide an industrial control cabinet air conditioner |

Range and precision

| test item | measuring range | accuracy |

| velocity measurement | 0km/h~170km/h | ± Within 0.5% or ±0.1% full scale |

| Four wheel speed deviation | Uniform speed: ≤0.1km/h When changing speed: ≤0.5km/h | |

| Reversible braking force | ≥6000N and meet GB7258-2017 | ± 1% full scale |

| pedal effort | 0~ 1000N | ± 1% full scale |

| Parking brake | 0~ 1000N | ± 1% full scale |

| Dynamic braking force | ≥3700N/ wheel | ± 2% or ±1% full scale |

Check the beat

Less than 110 seconds

Integrated hub testing equipment——MDT-2000

Contact Us

Keywords