Product Solutions

Contact Us

E-mail:

sales@iyasaka.cn

Telephone:

010-58732677/2955

Address:Room 20C, Unit 3, Building C, Chunyingdu Building, Zhilu, Haidian District, Beijing

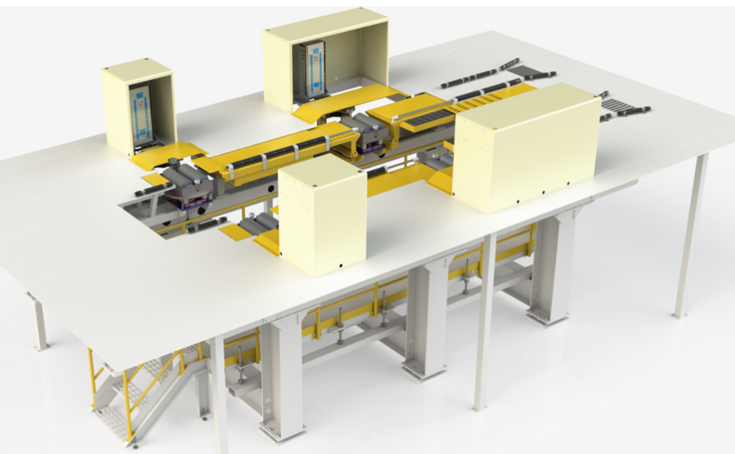

Non-contact four-wheel locator ——WAT-2000

Non-contact four-wheel locator ——WAT-2 0 00W heel A lignment S ystem—WAT-2000 Place of origin: ChinaManufacturing company: IYASAKA Testing conceptsA platform used to measure and evaluate parameters and components such as vehicle camber, caster, kingpin camber, kingpin caster, thrust angle, steering angle, etc.Meet the requirements of online adjustment of front beam and external inclination.Test principlesThe four-wheel positioning sensor utilizes MIRONs independently developed 3D laser sensing technology. By employing dynamic laser illumination matrix reconstruction, it generates tire surface 3D images at 10/20 Hz frequency. This enables accurate determination of front camber and caster angles through tire 3D modeling. The system can be configured with wheel bead height measurement units for vehicle body (wheel bead) height assessment. It also supports expandable functions including axle load measurement and steering angle monitoring.test itemtoe-inextraversionMain pin backward tilt/Main pin inward tilt (optional)Rim and eyebrow height measurement system (optional)Shaft weight measurement system (optional)Rudder Angle measurement function (optional)Test modelPassenger cars and commercial vehiclesProduct featuresMore test functionality and higher test qualityHigh measurement accuracy, small repeatability error and stable operationThe new floating mode of the drum unit has the characteristics of small friction, smooth sliding and sensitivity, which can help improve the repeatability of test data. At the same time, it also has the function of aligning the vehicle when detecting and adjusting the vehicles front lampIyasaka and Visicon are two laser options that adapt to a wide range of pricesThe modular design is simple to arrange, easy to maintain, high cost performance, low maintenance cost and use costImage processing patent technologyServo technology is used for centering and central torque feedbackThe floating platform uses air suspension technology to minimize mechanical resistance and has higher accuracyscope of supplyThe four-wheel positioning equipment of WAT-2000 includes:There are two sets of mainframe and vehicle driving channel, one set on each side (installed in the pit) There are two sets of shaft adjustment devices, one for each left and right channel (installed in the pit) There are 4 sets of floating plates driven by motor, one set for each wheel There are 4 sets of vehicle center positioning device, one set for each wheelOne set of lighting device for the pitOne set of operating platform in the pit (adjustable height)A set of cover plate, ladder, handrail and fence 3D laser sensor (Iyasaka/Visicon) 4 sets, one set per round (Visicon is more expensive)Electrical control cabinet (including mainstream PLC and PC) 1 set (including circuit, button indicator light, UPS, display, servo control, etc.)A set of steering wheel Angle tester and accessories (including instrument body/handheld home/charging base/calibrator)Drivers assistant display 3 sets (2 sets in the pit, 1 set on the ground)Drivers operation button box 1 set (model selection, start, end, reinspection, emergency stop, etc.)Barcode scanner or RFID reader (option)Static calibration frameDynamic car (optional)Four-wheel positioning inspection software IAMachVision For WAT (for OEM online inspection)Complete technical data, including Chinese and English version of data book (including electrical circuit diagram, operation manual, installation manual, etc.).essential parameterAllowable axle load (parameters can be customized according to requirements)2 000kg/axleAllowable wheelbase (parameters can be customized according to requirements)1940-2840/2300-3200/2600-3800, etc Test speed (dynamic test)About 4km/hRoller dimensionsFront roller (parameters are customized according to requirements)Internal width x external width( between centers )1250×2150mm1700mmOutside diameter x lengthØ186×450mmmmBack roller (parameters are customized according to requirements)Internal width x external width( between centers )1250×2150mm1700mmExternal diameter × face lengthØ186×450mmmmShaft spacing220mmRolling drum motor (passenger car)0.75kW, 4P,4 unitsRoller brakingPneumatic mechanical brake, can be maintainedRolling floating platformNew type of ball floatingAxis setting methodThe rear roller section is mobileShaft offset moving motorServo motor, 0.75kW, 2 unitstranslational speedGreater than 60mm/secMobile precision±1mmwayAutomatic movement, acceleration and deceleration servo controlTo the middle roller1) Static test modeThe vehicle is aligned2) Dynamic test modeVehicle center and test deviationRange and precisionprojectmeasurement rangeaccuracyrepeatability precisionremarkstoein±8°±1ˊ±0.2ˊMust be checkedcamber±5°±2ˊ±0.4ˊMust be checkedMain pin backward tilt (measuring the inner and rear tilt angles of the main pin by an external sensor)±15°±0.2°-Sampling itemsMain pin inclination (measuring the main pin